Compressor life cycle by Daikin

Overhaul

Overhauling Benefits

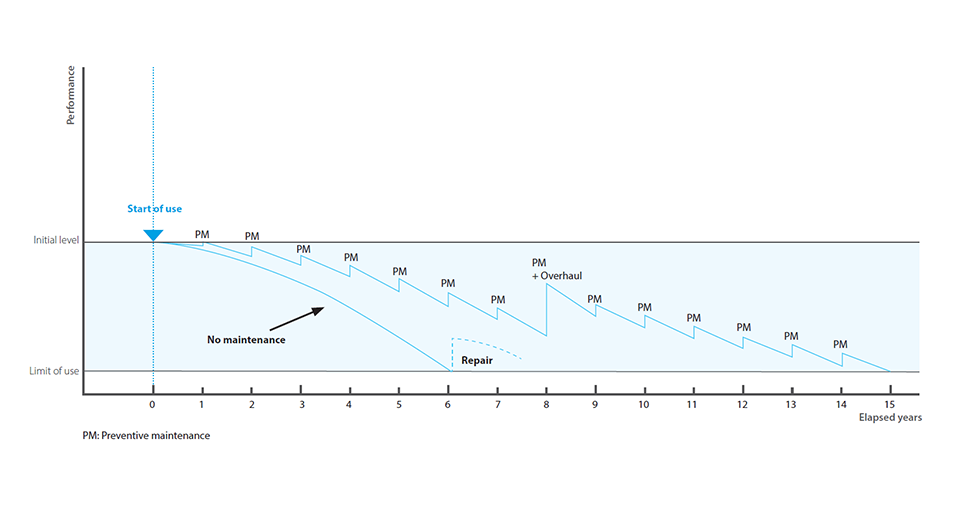

- Cost savings: Repairs are costly and preventive actions aim to reduce this for up to 50%

- Reduced downtime: Planned maintenance and interventions reduce the risk of downtime

- Improved reliability and performance: Wear and tear makes the equipment operate at a lower performance than originally

- Extend lifetime: The replacement of some of the main components assures your equipment’s life gets prolonged

- Planned intervention: To avoid surprises when the chiller is most needed, planning in the low seasons allows for better and cheaper interventions

- Peace of mind: Focus on your core business, and let Daikin take care of your chillers

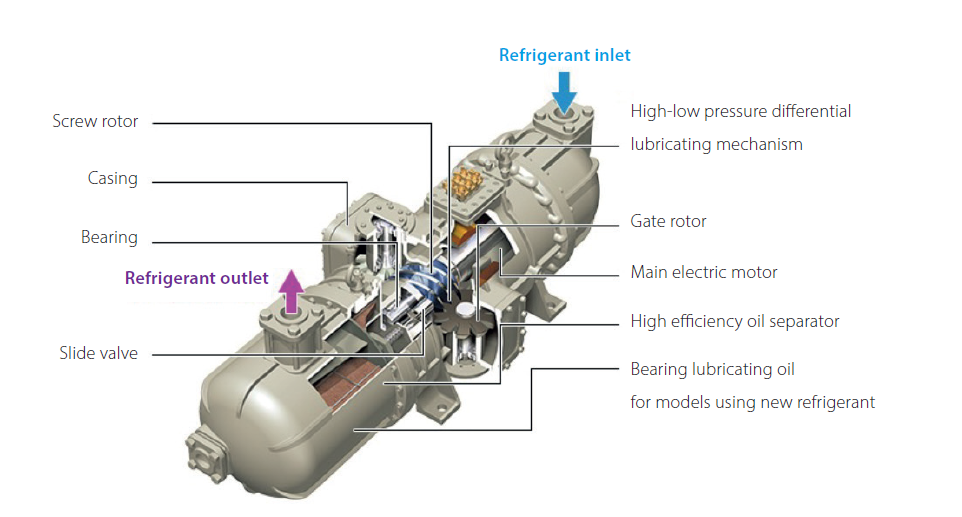

What is an Overhaul?

When to Overhaul?

The factory recommendation is that a major overhaul is to be done every 40.000 running hours of the compressor. For Screw chillers, a minor overhaul is to be done every 20.000 running hours. This is part of the chiller lifetime maintenance cycle in order to assure optimal performance and avoid breakdowns. Since it is a planned intervention, an overhaul can be scheduled during the low season to have the lowest impact possible on the customer’s operations.

Repair

Has your compressor broken down and you need to have a fast solution?

Your compressor can be repaired at a fixed price.

What is a Repair?

In case the compressor breaks down, we also offer the possibility of fully repairing the compressor. In this case, the compressor will need to be sent to the factory to be repaired.

It is always better to have a redundant chiller in place or rent one from us, not to affect your production.

Repair Benefits

- Cost savings, compared to purchasing a new chiller

- Time savings.

- Warranty: the repaired compressor will have a factory warranty